Grab bucket

Grab bucket

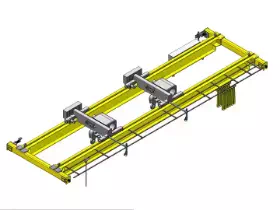

The QZ electric grab bridge crane primarily consists of a box-shaped bridge, a grab crab, a trolley traveling mechanism, an operator’s cab, and an electrical control system. The grab crab includes a switching mechanism and a lifting mechanism. The grab is suspended by four steel wire ropes from these two mechanisms. The switching mechanism drives the grab to close and collect materials. Once the grab is closed, the lifting mechanism is immediately activated to hoist the four evenly loaded wire ropes. For unloading, only the switching mechanism needs to be operated to open the grab and discharge the materials.

Except for the lifting mechanism, this crane is largely similar to a standard hook-type bridge crane.

Technical Advantages:

1.Customized according to the customer’s capacity replacement strategy, this intelligent crane aligns with green industry trends and is tailored to specific project site conditions.

2.It integrates intelligent systems such as PLC control, precise positioning, and anti-sway control, ensuring accurate positioning and high operational efficiency.

3.The crane features a wide-box weight-resistant structure with high fatigue resistance, suitable for harsh environments including high temperature, humidity, and dense fog.

4.With an intelligent sensing system, it enables automated material grabbing, placement, and transportation even in low-visibility, foggy conditions.

5.Remote scheduling and management systems allow for unmanned on-site operation, significantly reducing manual workload and improving operational safety.

The load handling device is the grab which is able to capture bulk materials.

In recent years, Henan Mine Crane has continuously increased its research and development efforts in intelligent, green, and lightweight cranes, and a large number of high-quality cranes have been applied to key engineering fields such as steel smelting, aerospace ships, and petrochemical industry.

This joint venture with Guangxi Yiji Iron and Steel to promote industrial transformation and upgrading, and to jointly build a 10 million tons metallurgical new material (steel) base, not only demonstrates the innovative and creative strength of Henan Mine Crane, but also lays a solid foundation for deep cooperation in technology innovation and other aspects between the two sides.